Plywood an yi shi da siraran siraran itace uku ko fiye da aka haɗa tare da manne.Kowane Layer na itace, ko ply, yawanci yana daidaitawa tare da hatsin da ke gudana a kusurwoyi masu kyau zuwa layin da ke kusa don rage raguwa da inganta ƙarfin yanki da aka gama.Yawancin plywood ana matse su cikin manya-manyan zanen gado waɗanda ake amfani da su wajen ginin gini.Za a iya samar da wasu guntun plywood zuwa sassauƙan maɓalli ko mahalli don amfani a cikin kayan daki, jiragen ruwa, da jirgin sama.

Yin amfani da siraran itacen itace a matsayin hanyar gini ya kasance kusan shekara ta 1500 BC lokacin da masu sana'ar Masarawa suka ɗaure ɓangarorin itacen ɓaure mai duhu zuwa wajen wani akwati na itacen al'ul da aka samu a cikin kabarin sarki Tut-Ankh-Amon.Daga baya Girkawa da Romawa suka yi amfani da wannan dabara don kera kayan daki masu kyau da sauran kayan ado.A cikin 1600s, fasahar yin ado da kayan ado tare da ƙananan katako sun zama sanannun da ake kira veneering, kuma guntu da kansu sun zama sanannun da ake kira veneers.

Har zuwa ƙarshen 1700s, an yanke sassan veneer gaba ɗaya da hannu.A shekara ta 1797, Sir Samuel Bentham ɗan ƙasar Ingila ya nemi haƙƙin mallaka wanda ke rufe na'urori da yawa don kera veneers.A cikin aikace-aikacen sa na haƙƙin mallaka, ya bayyana manufar laminating da yawa yadudduka na veneer tare da manne don samar da wani kauri yanki — na farko bayanin abin da muke kira plywood yanzu.

Duk da wannan ci gaban, ya ɗauki kusan wasu shekaru ɗari kafin laminated veneers sami wani kasuwanci amfani a waje da furniture masana'antu.A cikin kusan 1890, an fara amfani da katako mai laushi don gina kofofin.Yayin da bukatar ta karu, kamfanoni da dama sun fara kera zanen itacen da aka yi da katako da yawa, ba don kofofi kadai ba, har ma don amfani da motocin jirgin kasa, bas, da jiragen sama.Duk da wannan ƙarin amfani, manufar yin amfani da "zurfin dazuzzuka," kamar yadda wasu masu sana'a suka kira su da ba'a, sun haifar da mummunan hoto ga samfurin.Don magance wannan hoton, masana'antun katako sun hadu kuma a ƙarshe sun daidaita kan kalmar "plywood" don kwatanta sabon kayan.

A cikin 1928, an gabatar da zanen plywood na farko mai girman 4 ft da 8 ft (1.2 m ta 2.4 m) a cikin Amurka don amfani azaman kayan gini na gabaɗaya.A cikin shekaru masu zuwa, ingantattun manne da sabbin hanyoyin samarwa sun ba da damar yin amfani da plywood don aikace-aikace iri-iri.A yau, plywood ya maye gurbin katako da aka yanke don dalilai na gine-gine da yawa, kuma masana'antar plywood ya zama dala biliyan da yawa, masana'antu a duniya.

Fuskokin waje na plywood an san su da fuska da baya.Fuskar ita ce saman da za a yi amfani da ita ko gani, yayin da baya ya kasance ba a amfani da shi ko ɓoye.An san tsakiyar Layer da ainihin.A cikin plywoods tare da plies biyar ko fiye, tsaka-tsakin yadudduka ana kiran su crossbands.

Ana iya yin plywood daga katako, itace mai laushi, ko haɗin biyun.Wasu katako na gama gari sun haɗa da ash, maple, mahogany, itacen oak, da teak.Itace mai laushi da aka fi amfani da ita don yin plywood a Amurka shine Douglas fir, kodayake ana amfani da nau'ikan Pine, cedar, spruce, da redwood.

Haɗe-haɗe plywood yana da cibiya da aka yi da allo ko ƙaƙƙarfan katako da aka haɗa gefe zuwa gefe.An gama shi da fuskar bangon bango da baya.Ana amfani da plywood mai hade inda ake buƙatar zanen gado mai kauri sosai.

Nau'in manne da aka yi amfani da shi don haɗa sassan katako tare ya dogara da takamaiman aikace-aikacen plywood da aka gama.Softwood plywood zanen gado da aka tsara don shigarwa a kan waje na wani tsari yawanci yana amfani da resin phenol-formaldehyde a matsayin m saboda kyakkyawan ƙarfinsa da juriya ga danshi.Zanen Softwood plywood wanda aka ƙera don shigarwa akan ciki na tsari na iya amfani da furotin na jini ko mannen furotin waken soya, kodayake yawancin zanen ciki na softwood an yi su da irin wannan resin phenol-formaldehyde da ake amfani da shi don zanen waje.Itacen katako da ake amfani da shi don aikace-aikacen ciki da kuma gina kayan daki yawanci ana yin shi da resin urea-formaldehyde.

Wasu aikace-aikacen suna buƙatar zanen gadon filasta waɗanda ke da ɗan ƙaramin roba na filastik, ƙarfe, ko takarda da aka sanyawa guduro ko masana'anta da aka haɗe zuwa ko dai fuska ko baya (ko duka biyu) don ba wa farfajiyar waje ƙarin juriya ga danshi da ƙazanta ko don haɓaka fenti. rike kaddarorin.Irin wannan katakon ana kiran shi da rufin katako kuma ana amfani da shi a cikin gine-gine, sufuri, da masana'antar noma.

Ana iya lulluɓe sauran zanen katako da tabo na ruwa don baiwa saman saman kamannin kamala, ko kuma ana iya bi da su da sinadarai daban-daban don inganta juriyar harshen wuta ko juriya ga ruɓe.

Akwai faffadan nau'ikan plywood guda biyu, kowanne yana da nasa tsarin tantancewa.

An san aji ɗaya da gini da masana'antu.Plywoods a cikin wannan ajin ana amfani da su da farko don ƙarfinsu kuma ana ƙididdige su ta hanyar iyawarsu da kuma darajar veneer da ake amfani da su a fuska da baya.Iyawar fallasa na iya zama ciki ko na waje, ya danganta da nau'in manne.Makin veneer na iya zama N, A, B, C, ko D. N yana da ƙarancin lahani sosai, yayin da darajar D na iya samun kulli da tsaga.Misali, itacen da ake amfani da shi don yin ƙasa a cikin gida ana ƙididdige shi "CD na ciki".Wannan yana nufin yana da fuskar C tare da baya D, kuma manne ya dace don amfani a wurare masu kariya.Plies na ciki na duk gine-gine da plywood masana'antu an yi su ne daga matakin C ko D veneer, komai rating.

Sauran nau'in plywood da aka sani da katako da kayan ado.Plywoods a cikin wannan ajin ana amfani da su ne da farko don bayyanar su kuma an ƙididdige su a cikin tsarin saukowa na juriya ga danshi kamar Fasaha (Na waje), Nau'in I (Na waje), Nau'in II (Na ciki), da Nau'in III (Na ciki).Fuskokin su kusan ba su da lahani.

Girman girma

Plywood zanen gado Range a cikin kauri daga.06 a (1.6 mm) zuwa 3.0 in (76 mm).Mafi yawan kauri suna cikin kewayon 0.25 in (6.4 mm) zuwa 0.75 in (19.0 mm).Ko da yake ana iya yin ainihin, ƙugiya, da fuska da bayan takarda na plywood na kauri daban-daban, kauri na kowanne dole ne ya daidaita a kusa da tsakiya.Misali, fuska da baya dole ne su kasance daidai da kauri.Hakanan maɗaurin sama da ƙasa dole ne su kasance daidai.

Girman da ya fi dacewa don zanen katako da ake amfani da shi wajen ginin gini shine 4 ft (1.2m) faɗi da 8 ft (2.4m) tsayi.Sauran faɗin gama gari sune 3 ft (0.9m) da 5 ft (1.5m).Tsawoyin sun bambanta daga 8 ft (2.4m) zuwa 12 ft (3.6m) a cikin haɓaka 1 ft (0.3 m).Aikace-aikace na musamman kamar ginin jirgin ruwa na iya buƙatar manyan zanen gado.

Bishiyoyin da ake yin plywood gabaɗaya sun fi waɗanda ake yin katako ƙanana a diamita.A mafi yawan lokuta, an shuka su kuma an girma a wuraren da kamfanin plywood ya mallaka.Ana sarrafa waɗannan wuraren a hankali don haɓaka girma bishiyoyi da rage lalacewa daga kwari ko wuta.

Anan akwai tsarin aiki na yau da kullun don sarrafa bishiyoyi zuwa daidaitattun 4 ft da 8 ft (1.2 m ta 2.4 m) zanen gado na plywood:

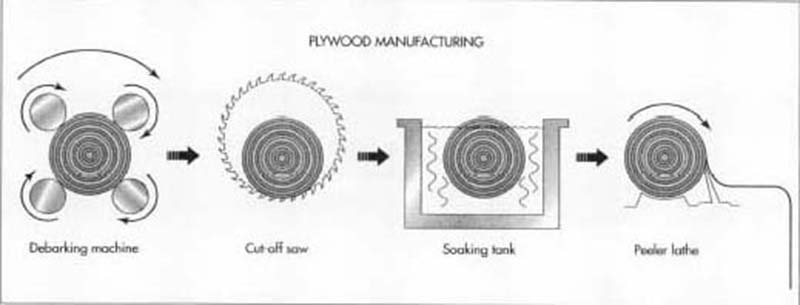

Ana fara cire katakon katako sannan a yanka su cikin tubalan peeler.Domin a datse tubalan a cikin filaye na veneer, ana fara jiƙa su sannan a kwasfa su cikin tsiri.

1 Zaɓaɓɓun bishiyoyi a wani yanki ana yiwa alama suna shirin sarewa, ko sarewa.Za a iya yankewa da sarƙar sarƙa mai ƙarfi da mai ko kuma tare da manyan ƙullun ruwa da aka ɗora a gaban motocin masu ƙafar ƙafa da ake kira masu faɗuwa.Ana cire gaɓoɓin daga bishiyoyin da suka fadi tare da sarkar sarka.

2 Ana jan kututturen bishiyar, ko katako, zuwa wurin da ake yin lodi ta motoci masu ƙafafu da ake kira skidders.An yanke katakon tsayi kuma ana loda su a kan manyan motoci don tafiya zuwa masana'antar katako, inda aka jera su a cikin dogayen tudu da aka fi sani da katako.

3 Kamar yadda ake buƙatar katako, ana ɗauko su daga cikin katako ta hanyar loda masu gajiyar roba kuma a sanya su a kan injin daskarewa da ke kawo su cikin injin cire barasa.Wannan injin yana cire haushin, ko dai tare da ƙafafun niƙa masu kaifi mai kaifi ko kuma tare da jiragen ruwa mai ƙarfi, yayin da katakon yana jujjuya shi a hankali game da doguwar kuturinsa.

4 Ana ɗauke da gungumen da aka cire a cikin injin niƙa akan sarkar sarka inda wata katuwar zato mai madauwari ta yanke su zuwa sassa kimanin 8 ft-4 in (2.5m) zuwa 8 ft-6 in (2.6m) tsayi, wanda ya dace da yin misali 8 ft. (2.4m) dogon zanen gado.Waɗannan sassan gungu an san su da tubalan peeler.

5 Kafin a yanke abin rufewar, dole ne a ɗora tubalan peeler a jiƙa don tausasa itacen.Ana iya yin tururi ko kuma a nutsar da tubalan cikin ruwan zafi.Wannan tsari yana ɗaukar sa'o'i 12-40 dangane da nau'in itace, diamita na toshe, da sauran dalilai.

6 Daga nan sai a kai bulogin bawon bawon da aka zazzage zuwa mashin bawon, inda za a jera su kai tsaye kuma a ciyar da su cikin lashin ɗaya bayan ɗaya.Yayin da lathe ke jujjuya shingen da sauri game da doguwar gajinsa, wuka mai tsayi mai tsayi tana barewa takardar veneer mai ci gaba da yin juzu'i daga saman shingen juzu'i a cikin 300-800 ft/min (90-240 m/min).Lokacin da aka rage diamita na toshe zuwa kusan 3-4 in (230-305 mm), ragowar itacen da aka fi sani da peeler core, ana fitar da shi daga lathe kuma ana ciyar da sabon shingen peeler a wurin.

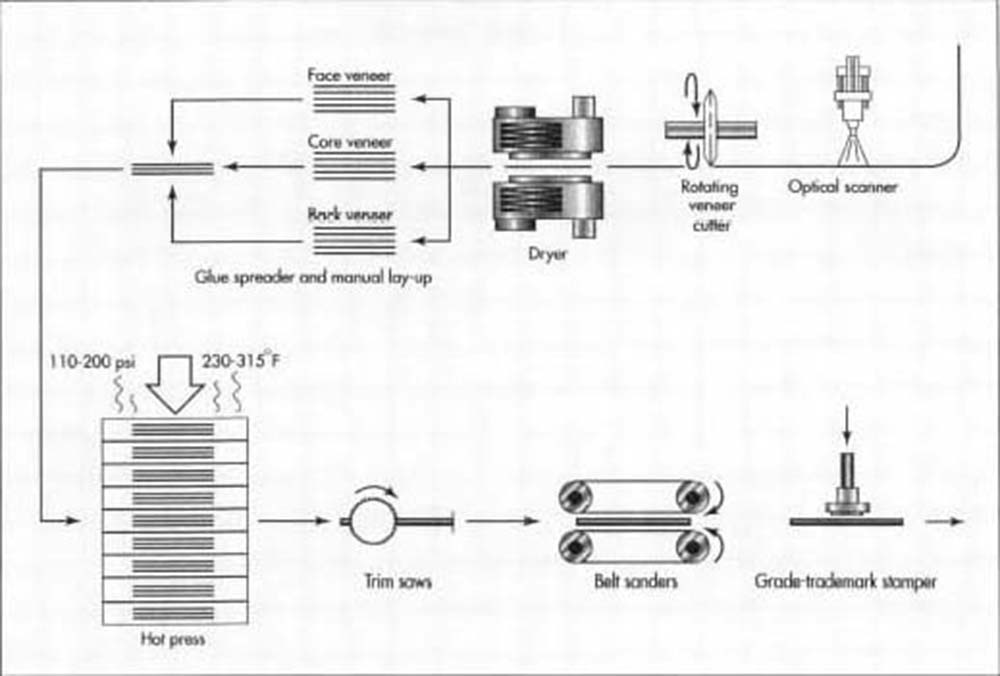

7 Za a iya sarrafa dogayen takardan veneer da ke fitowa daga / na bawon lathe ɗin nan da nan, ko kuma ana iya adana shi a cikin dogayen tire masu girma dabam ko raunata a kan nadi.A kowane hali, tsari na gaba ya haɗa da yanke veneer zuwa faɗin amfani mai amfani, yawanci kusan 4 ft-6 a (1.4m), don yin daidaitaccen zanen plywood mai faɗi 4 ft (1.2 m).A lokaci guda, na'urar daukar hoto na gani suna neman sassan da ke da lahani da ba za a yarda da su ba, kuma an cire su, suna barin ƙasa da daidaitattun faɗin faɗuwar veneer.

An raunata ɗigon rigar veneer a cikin nadi, yayin da na'urar daukar hoto ta gano duk wani lahani da ba za a yarda da shi a cikin itace ba.Da zarar an bushe veneer ɗin an yi digiri kuma a jera shi.An haɗa sassan da aka zaɓa na veneer tare.Ana amfani da latsa mai zafi don rufe murfin a cikin katako mai ƙarfi guda ɗaya, wanda za'a gyara shi da yashi kafin a buga shi da darajarsa.

8 Sa'an nan kuma ana jera sassan veneer kuma a jera su daidai gwargwado.Ana iya yin wannan da hannu, ko kuma ana iya yin shi ta atomatik ta amfani da na'urar daukar hoto.

9 Ana ciyar da sassan da aka jera a cikin na'urar bushewa don rage danshi kuma a ba su damar raguwa kafin a haɗa su tare.Yawancin masana'antar plywood suna amfani da na'urar bushewa wanda guntuwar ke motsawa ta cikin ɗaki mai zafi.A wasu na'urorin bushewa, jiragen sama masu tsananin gudu, iska mai zafi suna busa a saman sassan don saurin bushewar.

10 Yayin da sassan veneer ke fitowa daga na'urar bushewa, an jera su daidai gwargwado.Sassan ƙasan ƙasa suna da ƙarin veneer da aka spliced akan tef ko manne don yin guntun da suka dace da amfani a cikin yadudduka na ciki inda bayyanar da ƙarfi ba su da mahimmanci.

11 Waɗancan ɓangarori na veneer ɗin da za a girka madaidaita-madaidaicin cikin zanen gado uku, ko maɗaurin da ke cikin zanen fenti biyar—an yanke su zuwa tsayin kusan 4 ft-3 in (m1.3).

12 Sa’ad da aka haɗa sassan da suka dace na itacen ɓangarorin da aka yi amfani da su don gudu na musamman na plywood, tsarin jerawa da kuma haɗa gundumomin tare.Ana iya yin wannan da hannu ko ta atomatik tare da injuna.A cikin mafi sauƙi na zanen gado uku, an shimfiɗa murfin baya kuma an gudanar da shi ta hanyar shimfidar manne, wanda ke amfani da launi na manne zuwa saman saman.Gajerun sassa na core veneer an shimfiɗa su a kan manne a baya, kuma ana gudanar da dukan takardar ta cikin manne a karo na biyu.A ƙarshe, an ɗora murfin fuska a saman mannen core, kuma takardar an jera shi tare da wasu zanen gado suna jiran shiga cikin latsawa.

13 Ana ɗora zanen gadon manne a cikin latsa mai zafi mai buɗewa da yawa.latsa na iya ɗaukar zanen gado 20-40 a lokaci guda, tare da ɗora kowace takarda a cikin ramin daban.Lokacin da aka ɗora dukkan zanen gadon, latsa yana matse su tare a ƙarƙashin matsi na kusan 110-200 psi (7.6-13.8 mashaya), yayin da a lokaci guda dumama su zuwa zafin jiki na kusan 230-315 ° F (109.9-157.2 °). C).Matsin lamba yana tabbatar da kyakkyawar hulɗa tsakanin yadudduka na veneer, kuma zafi yana haifar da manne don warkewa da kyau don iyakar ƙarfi.Bayan tsawon mintuna 2-7, ana buɗe latsa kuma ana sauke zanen gado.

14 Sa'an nan ƙullun ɗin ya bi ta cikin tsattsauran tsattsauran ra'ayi, waɗanda za a datse su zuwa faɗin ƙarshensu da tsayinsu.Zane-zane mafi girma suna wucewa ta saiti na bel mai faɗin bel 4 ft (1.2m), wanda yashi duka fuska da baya.Matsakaicin zanen gado ana tabo yashi da hannu don tsaftace wuraren da ba su da kyau.Wasu zanen gado ana gudanar da su ta hanyar wani nau'i na madauwari na zato, waɗanda ke yanke ramuka mara zurfi a cikin fuska don ba da katakon siffa mai laushi.Bayan dubawa na ƙarshe, duk sauran lahani ana gyara su.

15 Abubuwan da aka gama suna hatimi tare da alamar alamar kasuwanci wanda ke ba mai siye bayanai game da ƙimar fallasa, daraja, lambar niƙa, da sauran dalilai.Zane-zane na alamar kasuwanci iri ɗaya an haɗa su a cikin tari kuma an ƙaura zuwa sito don jiran jigilar kaya.

Kamar yadda yake tare da katako, babu wani abu mai kama da tsararren katako.Duk guda na plywood suna da ƙarancin lahani.Lamba da wurin waɗannan lahani suna ƙayyade ƙimar plywood.Ma'auni na gine-gine da plywoods masana'antu an bayyana su ta Samfur Standard PS1 da Ofishin Ƙididdiga na Ƙasa da Ƙungiyar Plywood ta Amirka suka shirya.An bayyana ma'auni na katako da kayan ado na ANSIIHPMA HP wanda Cibiyar Ka'idodin Ka'idodin Ƙasa ta Amurka da Ƙungiyar Manufacturers ta Hardwood Plywood suka shirya.Waɗannan ma'aunai ba wai kawai suna kafa tsarin ƙididdigewa don plywood ba, har ma suna ƙayyadaddun gini, aiki, da ƙa'idodin aikace-aikacen.

Ko da yake plywood yana yin amfani da bishiyu daidai gwargwado-ainihin raba su tare da mayar da su wuri ɗaya cikin ƙaƙƙarfan tsari mai amfani - har yanzu akwai sharar gida mai yawa a cikin tsarin masana'anta.A mafi yawan lokuta, kusan kashi 50-75% na yawan amfanin itacen da ake amfani da shi a cikin bishiya ne ke juyewa zuwa plywood.Don haɓaka wannan adadi, ana haɓaka sabbin samfura da yawa.

Wani sabon samfuri ana kiransa allo daidaitacce, wanda ake yin shi ta hanyar yayyage duk log ɗin zuwa madauri, maimakon bare veneer daga gungumen kuma zubar da ainihin.Ana haɗe igiyoyi tare da manne kuma an matsa su cikin yadudduka tare da hatsi yana gudana a hanya ɗaya.Wadannan layukan da aka danne sannan ana karkata su a kusurwoyi madaidaici da juna, kamar katako, kuma an hade su tare.Madaidaicin allon madaurin yana da ƙarfi kamar plywood kuma farashi kaɗan kaɗan.

Lokacin aikawa: Agusta-10-2021